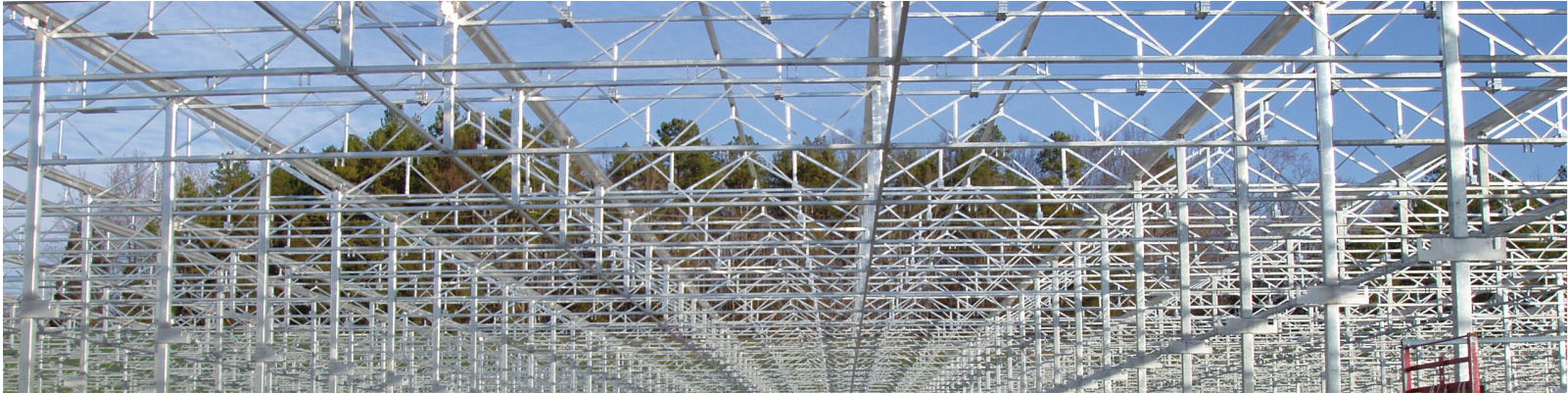

Venlo Greenhouses

The Bom Group designs and assembles different types of greenhouse. The Venlo greenhouse is the most-built type of greenhouse worldwide. It is made of glass, with a skeleton of galvanised steel and aluminium.

In the Netherlands the greenhouses are mainly of glass, of which there are two main types: the Venlo greenhouse and the wide-span. For a number of years, The Bom Group has been developing new types of greenhouse, such as the closed, semi-closed and energy greenhouses. These greenhouses are suitable for a Dutch system called The New Cultivation (HNT), using which as little energy as possible is lost.

In Venlo greenhouses, the span of the trusses is available in dimensions with a bay width of 8.00, 8.54, 9.60, 12.00 and 12.80 metres. Custom work is also possible, and every The Bom Group greenhouse is fully adapted to local climatic conditions.

Twinlight® construction

For the new generation of 'high'-roof greenhouses, The Bom Group has developed the Twinlight® construction. As the greenhouse column consists of two narrow, thin uprights rather than a large solid tube, more light is let through to the crop and less material is needed. The cultivation area remains the same because the underside of the downwards-tapering column is not wider than the dolly. The top of the custom upright has the same width as the truss so that the screen always closes off properly. The innovative Twinlight® construction with its smart cross-connection makes taller greenhouses possible. For you, this means a more consistent cultivation climate.

Glass types

Light is one of the primary growth factors for plants. When a greenhouse is designed, much attention is paid to this so that a minimum of light-interrupting factors are present. Growers pay a great deal of attention to matters such as increased light transmission.

AR glass features an anti-reflection coating; this ensures greater light transmission. For direct light, this is around 5% higher than standard horticultural glass, and for diffuse light 7% higher. A substantial increase in production is possible due to this. Because the light transmission is greater for diffuse light and when the sun is lower, the transmission is beneficially affected particularly in the winter.

Further, in the development of horticultural glass, ever more attention is being paid to diffuse glass.

In diffuse glass, the light entering is distributed in a different way and is scattered more in the greenhouse (haze). In this way, there is a reduced shadow effect in the greenhouse and better distribution of the light. Diffuse light penetrates better into the crop, so that photosynthesis is made more efficient. This in turn allows increased production to be realised. Particularly with tall-growing crops such as tomato, sweet pepper and cucumber, this is a great advantage.

Greenhouse roof systems

When choosing greenhouse roof material, a number of assessment criteria are significant. A grower particularly wants the greenhouse roof material to enable optimal production at modest cost. Other decision criteria are translucency and energy savings. Also, the degree to which the greenhouse roof allows UV radiation through may play a role. Further, the choice of roof affects the reduction of insect pests, moulds and viruses. At thee Bom Group, we supply you your greenhouse with our own greenhouse roof systems. They are resistant to the most severe weather conditions and feature our innovative aluminium PB Gutter.

Ventilation systems

Natural ventilation is one of the primary ways of controlling the humidity and temperature in a greenhouse. Greenhouse ventilation systems serve to air the greenhouse via roof vents to maintain the correct interior climate. Depending on the local circumstances, this may be via roof vents mounted alternately or via a continuous ridge ventilation system. With the ridge system, ventilation takes place via two roof vents per bay, one on each side over the whole length of the bay.

F-Clean greenhouses

In collaboration with AGC Green-Tech (Japan), the Bom Group has developed its own F-Clean® greenhouse. F-Clean® is a film material that looks like plastic film, but behaves like a membrane, which means it has to be tensioned. It is available in clear and diffuse versions and may be installed in both a single and a double layer. A greenhouse roof of double-layer F-Clean®, which has a diffuse inner layer, is continuously inflated into cushions by an inflation system. An energy saving of approx 30% is possible through use of two layers of F-Clean®. F-Clean® is already used on a large scale in cabriolet greenhouses. In these, the tensioning system is integrated into the roof construction.

Cabriolet greenhouse

The cabriolet greenhouse is the ideal type for growers who want to harden off their crop in the outside air, but also want to cultivate in a protected environment. There is a choice from two types of ventilation mechanism, namely direct rack and pinion drive or the push-pull system. The Bom Group’s cabriolet greenhouse consists of a Venlo structure with an aluminium roof and may be implemented in glass, film or plastic glazing or F-Clean®.

Solar greenhouse

With the depletion of fossil energy sources, the application of solar energy in glass horticulture is becoming more topical. Within the horticulture sector, more and more work is being done on the use of solar energy for heating and electricity generation.

One of the options for harvesting and employing solar energy is the semi-closed (Sunergy®) greenhouse. In the summer, this is mechanically cooled; the solar heat is harvested and stored, and in the winter used for heating. Besides the energy-efficient greenhouses such as the Sunergy® greenhouse, the Bom Group has developed innovative solutions for generating solar energy.

Solar panels integrated into our modern greenhouse roof provide electricity generation. In this way, you have a good energy source available, and you contribute optimally to the environment.

Semi-closed greenhouse

A semi-closed greenhouse is mechanically cooled in the summer with a heat pump. This involves harvesting the sun’s heat and storing it in order to use it for heating in the winter.

Semi-closed cultivation is aimed at reducing ventilation, and from an energetic viewpoint is beneficial for (unilluminated) fruit-vegetables, tropical pot plants and cultivation where both heat and cold are needed.

How does it work?

1. In the greenhouse, a top cooling system is installed in order to reduce the daytime temperature.

2. The system only goes into operation at a previously-set level of insolation.

3. In the evening, we reduce the greenhouse temperature rapidly, to the plants’ benefit.